DC circuit breakers refer to circuit breakers used in DC power distribution systems from overcurrent and potential hazards. They perform the following functions:

Interrupt the flow of current when it exceeds a predefined threshold.

Protect electrical components from damage caused by excessive current.

Prevent electrical fires and other safety hazards that can result from overcurrent conditions.

Generally applicable to solar photovoltaic power generation and power distribution systems, battery energy storage systems, new energy vehicle DC charging systems, etc.

A system in which the input power supply terminal of the circuit breaker is DC current.

General DC circuit breakers include DC MCB (Miniature Circuit Breaker), DC MCCB (DC molded case circuit breaker), and Type B RCD (Residual Current Device).

1. Current detection

DC circuit breakers first require a current sensing mechanism to monitor the current levels in the circuit. This is usually achieved through a built-in current sensor, which can be resistive, current transformer (CT) or other type of sensor. When the current exceeds a preset safety threshold, the sensor triggers the circuit breaker’s protection mechanism.

2. Signal processing

Once an abnormal current is detected, the sensor sends a signal to the circuit breaker’s control unit. The control unit evaluates this signal and determines whether measures need to be taken to interrupt the circuit. In some advanced DC circuit breakers, this evaluation process may include complex algorithms to distinguish between true faults and temporary current fluctuations.

3. Circuit breaking action

If the control unit determines that the circuit needs to be opened, it activates the mechanical or electronic switching portion of the circuit breaker. In a mechanical circuit breaker, this may involve a fast-acting spring mechanism that rapidly separates the circuit breaker’s contacts, interrupting the current flow. In electronic circuit breakers, this may involve semiconductor switching devices such as transistors or thyristors, which can switch states very quickly.

4. Arc suppression

During the process of breaking a circuit, arcing may occur as the current attempts to maintain its path. Arcing can generate high temperatures, damage equipment, and possibly cause fires. Therefore, DC circuit breakers often contain arc suppression devices that rapidly cool the arc and dissipate its energy to prevent the arc from causing damage to the circuit breaker itself or connected equipment.

5. Reset and restore

Once the circuit is disconnected, the system can be safely inspected and repaired. After the problem is resolved, the circuit breaker can be reset manually or automatically. Some DC circuit breakers have an auto-reset feature that allows them to automatically restore connections after confirming that the circuit is safe. However, for certain types of failures, a manual reset may be required to ensure the safety of the system.

DC circuit breakers come in various types, each with its unique features and applications:

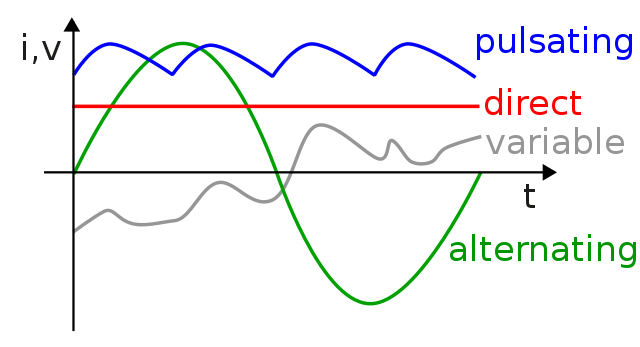

Direct current (DC) is a type of electrical current that flows in one constant direction. It is generated by sources such as batteries, solar panels, and fuel cells. Unlike alternating current (AC), which periodically changes direction, DC maintains a consistent flow, making it the preferred choice for many electronic devices and systems.

Direct current offers several advantages over alternating current:

Efficiency: DC systems typically experience fewer energy losses compared to AC systems.

Compatibility: Many electronic devices, such as computers and smartphones, require DC power to operate.

Simplicity: DC systems can be easier to design and maintain due to their constant voltage and current levels.

DC miniature circuit breaker MCB is specially designed for direct current (DC) circuit applications and is used for over-current and short-circuit protection in electrical appliances or electrical equipment.

DC MCB and the AC MCB are same functions. but, the usage scenarios of AC MCB and DC MCB are different.

DC MCB mostly uses for direct current (DC) systems application, such as new energy, solar photovoltaic (PV) and Solar cell energy storage system. The voltage state of DC MCB is generally DC 12V-1500V.

The difference between AC MCB and DC MCB in physical parameters on products.

The AC MCB are marked as LOAD and LINE on products, and the DC circuit breaker symbol marked as positive (+), negative (-) signs and the direction of the current on products.

DC MCCB (DC Molded Case Circuit Breaker) are ideal for energy storage, transportation, and industrial DC circuits.

DC molded case circuit breaker with same functions of AC MCCB, it has overload and short-circuit protection functions for high-current power distribution systems.

They are also used in ungrounded battery supply circuits for emergency back-up and standby power. Available up to 150A, 750 VDC and up to 2000A, 600 VDC. For DC breakers used in grounded photovoltaic systems in solar installations, application engineering and review ensures protection requirements are met.

DC MCCB (DC Mold Case Circuit Breaker) is a circuit control protection device for energy storage, transportation and industrial DC circuits. They are also used in ungrounded battery-powered circuits to provide emergency backup power and backup power. TONGOU produce high voltage dc circuit breaker,TONGOU DC MCCB can provide up to 150-800A, 380V-800V DC.

The signal of AC current is constantly changing its value for every second. The circuit breaker arc will be extinguished at 0 volts, and the circuit will be protected from big current.

But the signal of DC current is not alternating, it works in a constant state, and the voltage value will only change when the circuit is tripped or the circuit is reduced as a certain value.

Otherwise, the DC circuit will provide a constant voltage value for every second of a minute. Therefore, since there is no 0 volt point in the DC state, it does not suggest that use a AC circuit breaker for the DC state.

Choosing the right DC circuit breaker involves careful consideration of several key factors to ensure it meets your specific requirements and operational needs. Here’s a step-by-step guide to help you select the appropriate DC circuit breaker:

1. Understand Your Application

Identify the system voltage: Determine the operating voltage of your DC system. Common DC voltages include 12V, 24V, 48V, 110V, 220V, and higher, especially in industrial and renewable energy applications.

Determine the application type: Consider whether the breaker is for residential, commercial, industrial, or renewable energy applications (such as solar PV systems).

2. Determine the Current Rating

Calculate the full-load current: Add up the total current draw of all the devices connected to the circuit. This will give you the full-load current.

Select a breaker rating: Choose a breaker with a current rating that is 125% to 150% of the full-load current. This provides a safety margin and helps prevent nuisance tripping.

3. Interrupting Capacity

Check the interrupting rating: Ensure the circuit breaker can safely interrupt the maximum fault current that could occur in your system. The interrupting capacity should be higher than the maximum short-circuit current of the system.

4. Trip Curve and Characteristics

Choose the trip curve: Select a trip curve (B, C, D, etc.) that matches your application. The trip curve determines how quickly the breaker will trip under overload conditions.

Type B: Trips at 3-5 times the full load for residential circuits with lighting and heating.

Type C: Trips at 5-10 times the full load for general commercial applications.

Type D: Trips at 10-20 times the full load for industrial use with motors or transformers where high inrush currents occur.

5. Environmental Considerations

Ambient temperature: Consider the operating environment. High temperatures can affect the performance of circuit breakers. Choose a breaker that can operate reliably within the temperature range of the application.

Enclosure and mounting: Decide on the type of enclosure (e.g., NEMA or IP rating) if the breaker will be used in a harsh environment. Also, consider the mounting type (panel mount, DIN rail, etc.).

6. Additional Features

Remote trip and monitoring: Some applications may require remote tripping capabilities or integration with monitoring systems. Ensure the breaker you choose supports these features if needed.

DC-specific characteristics: Make sure the breaker is specifically rated for DC applications, as AC and DC circuit breakers have different arc-extinguishing mechanisms.

7. Compliance and Standards

Check for certification: Verify that the DC circuit breaker complies with relevant industry standards and certifications (e.g., UL, IEC) to ensure safety and reliability.

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | 29 |

| 30 | 31 | |||||

The EU trademark “tongou” (Registration No. 018630309) is owned by Changyou Technology (Zhejiang) Co., Ltd. We position ourselves as providers of intelligent product solutions for high and low voltage electrical systems, taking on solving customers’ pressures and challenges as our responsibility and creating value for them. We utilize intelligent products to serve global customers, making life smarter and more convenient to benefit your life.

Marine Economic Development Demonstration Zone, Wenzhou City, Zhejiang Province, China

Sales: [email protected]

After-sales: [email protected]

© 2026 Changyou Technology. All Rights Reserved.